In the past machine machining was all about precision, reliability, and speed. However, in today’s high-tech manufacturing environment efficiency is the most important factor. Tools you use directly influence your profit margins regardless of whether you’re producing components for aerospace, automotive components as well as high-tech electronic products. Indexable drills, high speed drills, tungsten-carbide end mills and threading inserts are all essential.

They aren’t just updates to old software. They’re an intelligent way to minimize downtime, lowering overall costs and delivering superior results using less effort. Let’s take a closer look at how each helps manufacturers drill deeper in order to cut with precision and finish faster.

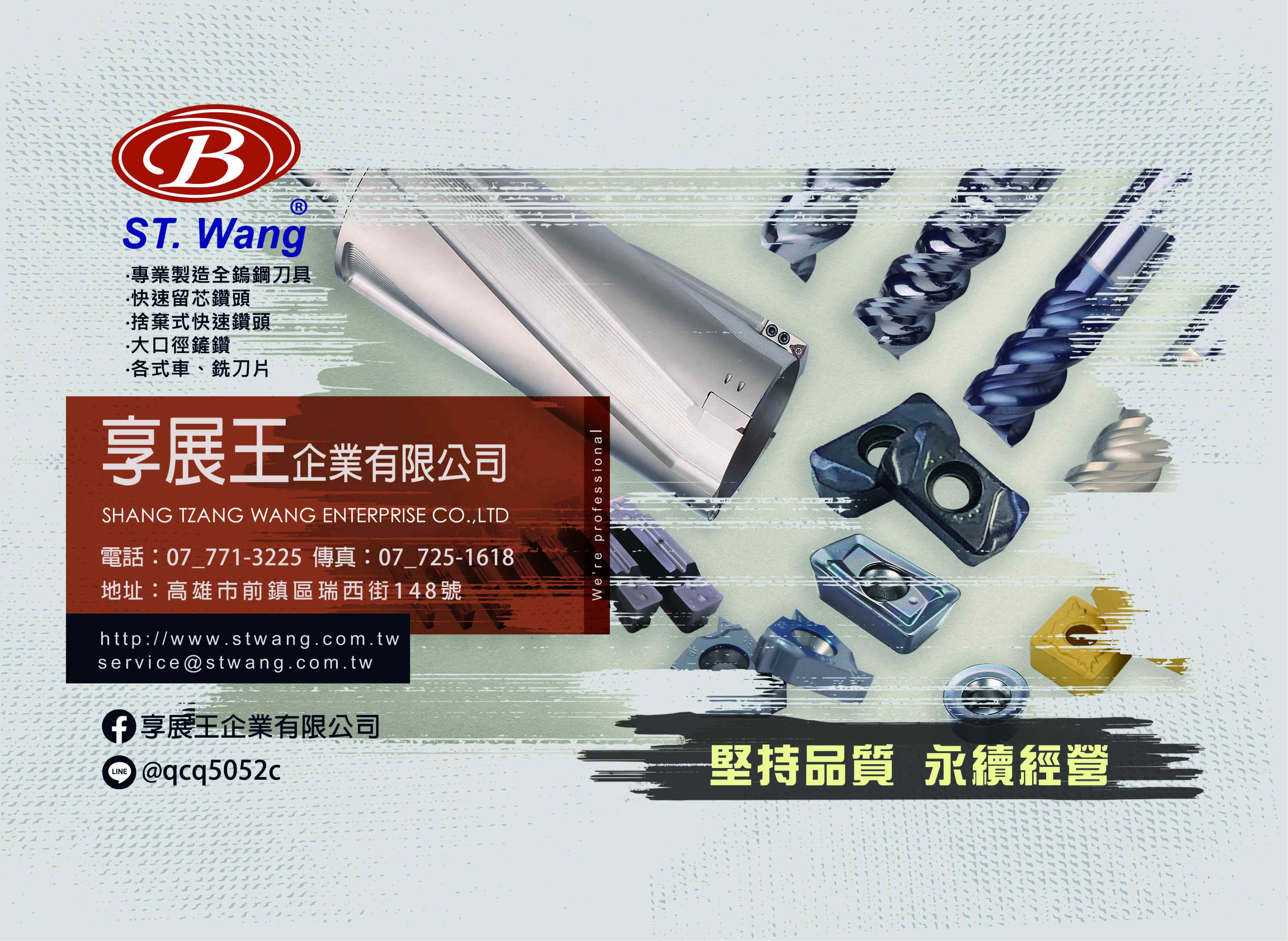

Image credit: stwang-tw.com

Indexable Drills: More Holes, Less Hassle

Drilling holes of a large size used to be expensive and laborious. Drills made of solid material wore out rapidly needing sharpening, and, in many cases, slowed production lines. Machine operators are increasingly using indexable drill. You can swap out inserts, not the entire tool if it gets dull.

What makes indexable drills distinctive is their performance. They’re made for long runs, performance that is heavy-duty, and easy maintenance. With interchangeable inserts help can reduce waste, lower tool inventory, and make sure your machines run longer. SHANG TZANG WANG ENTERPRISE, CO., LTD offers disposable core-stays with constant performance for large-diameter machines. This upgrade is perfect for shops who perform regular drilling and machining of holes. This can help them save the time and effort they spend every week.

High Speed Drills are Designed to meet the needs of today’s customers

High-speed drills are used in a production setting where time is of the essence. They are designed to run fast and precise without sacrificing speed. They are a great choice for strong materials and rapid cycle times. They’re employed in everything from medical precision components to high-volume automotive parts.

Modern high-speed drills come with designed flutes that are optimized and cutting-edge coatings that prevent the accumulation of heat, cut down on friction and increase time of use. This means less breakage as well as fewer changes to the tool and more parts going out the out the. Moving to a high-speed drilling is a fantastic option for any machinist that is frustrated by a damaged tool mid-cycle.

Tungsten Carbide End Mills: Reliable Performance Cut After Cut

When it comes to milling, tungsten carbide end mills are the workhorses of the shop floor. These end mills are known for their resistance to heat and hardness. They also can mill through tough materials without losing edge sharpness. They are dependable to complete any job, from roughing large sections or finishing corners.

Their versatility is what makes end mills crafted from tungsten carbonide special. They are able to be modified to meet different applications that range from aluminum to titanium with different flute count and Helix angles. For machinists that require accuracy and endurance, carbide end mills provide the ideal balance between aggressive material removal as well as clean surface finishes.

Threading Inserts: Tiny Tools, Big Impact

The creation of threads may appear to be a minor part of the process, but it is among the most important. A bad thread can ruin an otherwise perfect part. It is essential to choose an insert for threading that is of top quality. These replaceable, small tools are designed to cut threads on the side or inside the nut using precision and reliability.

Contrary to conventional taps and dies which wear unevenly threading inserts provide consistent results over many cycles. The tool can be adjusted to the next cutting point when one of the edges is dull. It’s not necessary to remove it or regrind. It’s fast, easy, and cost-effective. The durability of threading inserts is crucial to machine builders. With the right insert you’re assured that your threads will be perfect the first time no second passes, no rework, and no worries about part rejection.

The Bottom Line

Modern machining is time-sensitive. You can’t waste it. The most efficient shops today are shifting towards more efficient and more adaptable tools. These advanced cutting tools don’t only improve precision, they also simplify workflows, cut down on changeovers and extend the life of usable tools. What’s the outcome? The results? Less time spent attempting to solve problems, and more time is focused on producing precision parts. In a market where greater demand and a tighter margin are commonplace and tools that operate more effectively give companies the competitive edge.